{{ userInfo.nickname }}

ID: {{ userInfo.uid }}

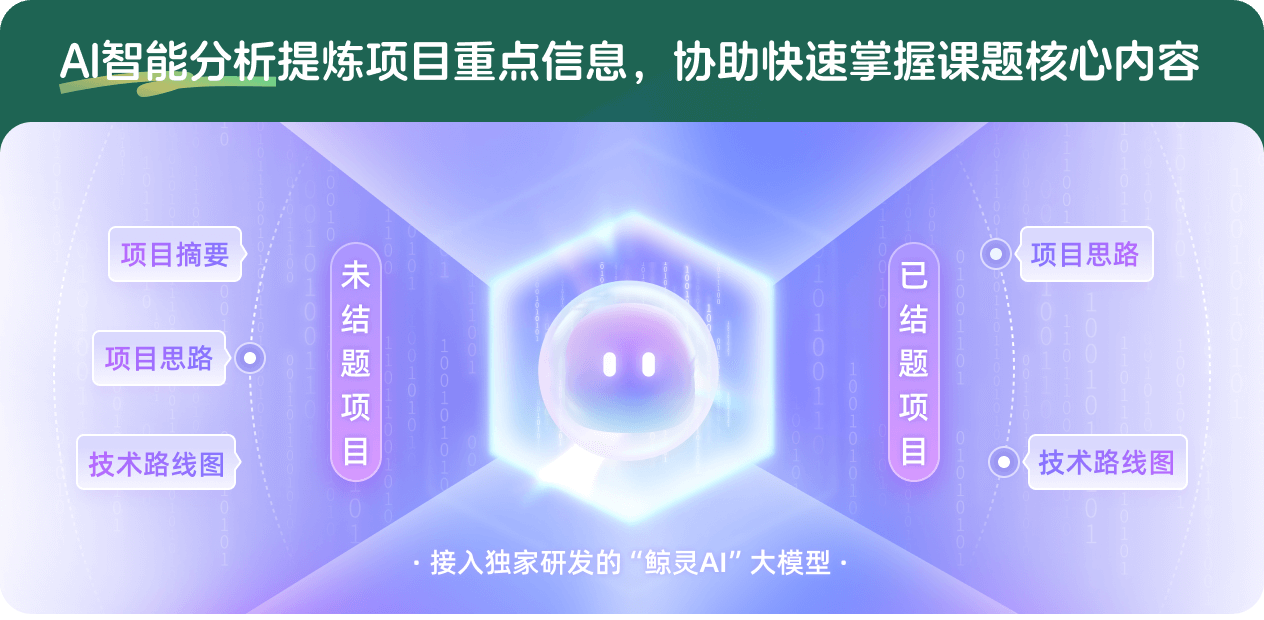

AI智能选题

让AI助力课题探索,轻松get研究热点与课题思路

AI智能选题

让AI助力课题探索,轻松get研究热点与课题思路

基金查询

75w+国自然、830w海外基金数据,科研动向轻松掌握

基金查询

75w+国自然、830w海外基金数据,科研动向轻松掌握

立项选题分析

透析历史立项课题数据,洞察高相关度选题

立项选题分析

透析历史立项课题数据,洞察高相关度选题

学科趋势分析

洞悉学科发展趋势,发现学科潜在热点

学科趋势分析

洞悉学科发展趋势,发现学科潜在热点

独家科研课程

国自然大牛手把手传授课题技巧,助力课题高效发表

独家科研课程

国自然大牛手把手传授课题技巧,助力课题高效发表

前沿课题资讯

最新国家资讯,掌握一手国家科研动向

前沿课题资讯

最新国家资讯,掌握一手国家科研动向

数据更新时间:{{ journalArticles.updateTime }}

数据更新时间:{{ journalArticles.updateTime }}

数据更新时间:{{ monograph.updateTime }}

数据更新时间:{{ sciAawards.updateTime }}

数据更新时间:{{ conferencePapers.updateTime }}

数据更新时间:{{ patent.updateTime }}

作者:{{ showInfoDetail.author }}

graph TD

A[研究起始] --> B[文献回顾与假设提出]

B --> C[实验设计与方法学准备]

C --> D[A型流感病毒感染模型建立]

D --> E[TRIM2与病毒RNA相互作用分析]

E --> F[TRIM2对IFN-β启动子活性的影响]

F --> G[IFN-β表达水平测定]

G --> H[TRIM2功能丧失与获得研究]

H --> I[数据收集与分析]

I --> J[结果解释与科学验证]

J --> K[研究结论与未来方向]

K --> L[研究结束]