AlGaN based-deep ultraviolet (UV) LEDs have broad application prospects in sterilization, biological detection and communication. However, the realization of high efficiency of deep UV LED has to face a lot of challenges, poor epitaxial quality, low light extraction efficiency, large thermal effect, poor reliability have restrict its development. In view of the above problems, this project intends to reduce the dislocation density and internal stress of the epitaxial layer of deep ultraviolet LED by embedding air cavity structure, and it is also solve the chip cracking and damage caused by laser lift-off process in the preparation of vertical structure devices. The effect of different sizes and fill factor on the quality of epitaxial layer, luminescence characteristics and laser lift-off damage of deep UV LEDs was studied. The N polar n-AlGaN photonic crystal structures were fabricated to improve the light extraction efficiency of deep UV LED. In addition, the key technologies of the vertical fabrication processes such as bonding, laser lift-off, dry etching and ohm contact were optimized to achieve high efficiency of vertical deep UV LED device. The implementation of the project provides an effective way to solve low quantum efficiency, large thermal effect and poor reliability in deep ultraviolet LED devices, and lays a foundation for realizing high efficiency and high power vertical structure of deep ultraviolet LED devices.

AlGaN基深紫外LED在杀菌、探测、通信等领域具有广阔的应用前景。然而,实现高效、大功率的深紫外LED仍然面临着巨大的挑战,外延质量差、光提取效率低、热效应大、可靠性差等问题严重制约着其发展。针对以上问题,本项目拟通过在外延层中嵌入空气腔结构来降低深紫外LED外延层位错密度及内应力,并同时解决垂直结构器件制备中激光剥离导致的芯片龟裂和损伤问题。研究不同尺寸、不同占空比空气腔结构对深紫外LED的外延质量、发光特性及剥离缺陷的影响机理。拟通过N极性n-AlGaN光子晶体结构提高深紫外LED光提取效率,研究光子晶体结构对深紫外LED的光极性调试规律。此外,拟通过提出垂直结构工艺中键合、剥离、刻蚀、电极蒸镀等关键技术的优化方案,制备出高效的垂直结深紫外器件。项目的实施为解决深紫外LED器件中内量子效率低、热效应大、可靠性差等问题提供有效途径,为实现高效大功率垂直结构深紫外LED器件奠定基础。

基于第三代半导体氮化镓(GaN)的发光二极管(LED)发光波长涵盖可见光和紫外波段,在照明、显示、工业固化、医疗卫生和通信探测等领域有着广泛的应用,深刻改变了人们的生活。然而,随着发光波长变短,Al组分相应增大, LED的发光效率逐渐降低。发光波长小于365 nm,尤其是200~280 nm的UVC波段深紫外LED的外量子效率基本在15%以下,商业产品的EQE甚至只有5%左右。这主要是由于AlGaN材料从外延生长到器件制备的技术挑战,如外延缺陷密度高、p型掺杂困难和载流子注入效率低等问题导致内量子效率低。而即使在外延上解决了这些问题,如何提升DUV LED的光提取效率仍是难点。本项目通过激光加工和纳米压印技术分别制备出微米和纳米级凹形图形化蓝宝石衬底结构, 并将这种图形化衬底通过金属有机气相沉积技术成功制备了具有空气腔结构的深紫外LED外延片,并研究了不同尺寸图形化衬底对外延结构的影响分析。在垂直结构深紫外LED芯片工艺制备中,这种结构可使得蓝宝石衬底与外延层平面接触,不会存在剥离能量不均的问题,并且具有更小的接触面积,更有利于芯片制备中的衬底转移工艺。此外,提出Ni/Al/Pt作为欧姆接触层和反光层,实现了低欧姆接触和高反射率的优化特性。研究了光子晶体结构对深紫外 LED的光提取效率的影响,分析光子晶体结构深紫外 LED的光学模式调控和偏振特性,并通过实验制备探索稳定可靠的光子晶体深紫外 LED工艺,提高器件的光电性能。

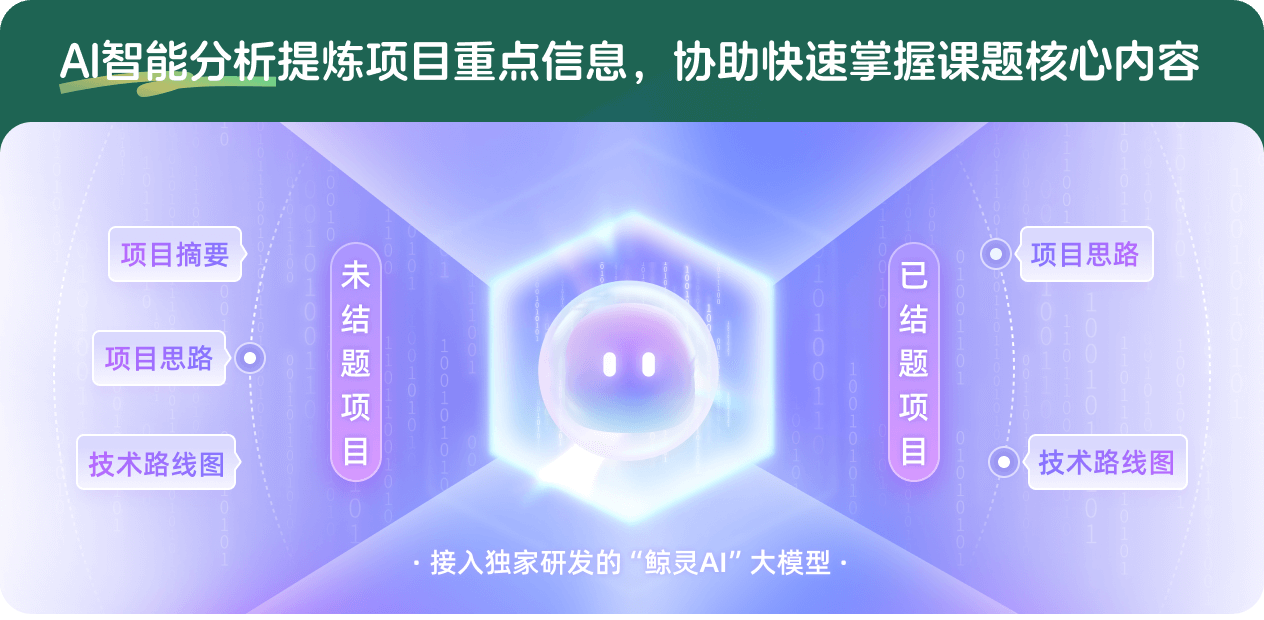

AI智能选题

让AI助力课题探索,轻松get研究热点与课题思路

AI智能选题

让AI助力课题探索,轻松get研究热点与课题思路

基金查询

75w+国自然、830w海外基金数据,科研动向轻松掌握

基金查询

75w+国自然、830w海外基金数据,科研动向轻松掌握

立项选题分析

透析历史立项课题数据,洞察高相关度选题

立项选题分析

透析历史立项课题数据,洞察高相关度选题

学科趋势分析

洞悉学科发展趋势,发现学科潜在热点

学科趋势分析

洞悉学科发展趋势,发现学科潜在热点

独家科研课程

国自然大牛手把手传授课题技巧,助力课题高效发表

独家科研课程

国自然大牛手把手传授课题技巧,助力课题高效发表

前沿课题资讯

最新国家资讯,掌握一手国家科研动向

前沿课题资讯

最新国家资讯,掌握一手国家科研动向